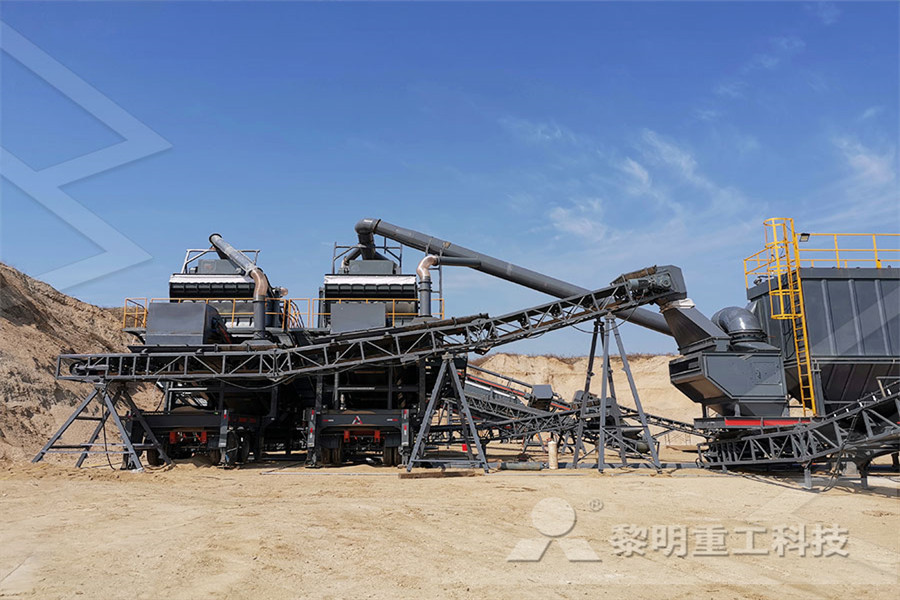

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

BEST Feed Plant Layout and Design from ABC Machinery

The factory plant, equipment, road, pipeline and ancillary equipment are combined to form a complete feed plant which has a reliable supply of raw materials, effective feed production line, power supply, water supply and sales markets, at the same time, has the Bulk Feed Loadout Bins Number of bulk product bins based on amount of feed made, number of products made, truck capacity, available layout of the mill is started Provision for future equipment and systems must be included in initial mill design Title: Feed Mill DesignFeed Mill DesignHygienic food factory design provides: Defence against external factory hazards Defence against internal factory hazards no harbourage sites and ease of cleaning Internal flows of people, product, packaging, air and wastes to prevent crosscontamination Security against deliberate contaminationHygienic Design of Food Manufacturing PremisesSep 27, 2018 When starting cattle feed manufacturing business or setting up a cattle feed processing plant, you have to make a complete business plan, make customized feed mill layout designYou should also study your customers the animal varieties they keep and the market trendSetup a Cattle Feed Processing Plant: Business Plan Eng Guide Index Screw Diameter (Inches) Capacity (Cubic Feet per Hour) Recommended Horizontal Feeder Screw Speed (RPM) 6 400 179 9 1,300 162 12 3,000 160 16 6,000 127 Note: The horizontal screw feeder speed recommendations are based on calculations at full pitch and 45% trough loading The horizontal screw []Vertical Screw Conveyor Feeder Guidelines Engineering Guide

6 LAYOUTS AND CONSTRUCTION WORK

Figure 69 Proposed layout and flow plan for 2 t/day handpeeling shrimp processing plant Figure 70 Flow chart for processing large shrimp Figure 71 Flow chart for whole fish freezing Figure 72 Proposed layout for whole fish freezing 623 Floors Floors should be hardwearing, nonporous, washable, well drained, nonslip and resistant to possible attack from brine, weak ammonia, fish oils Bulk Feed Loadout Bins Number of bulk product bins based on amount of feed made, number of products made, truck capacity, available layout of the mill is started Provision for future equipment and systems must be included in initial mill design Title: Feed Mill DesignFeed Mill DesignFigure 69 Proposed layout and flow plan for 2 t/day handpeeling shrimp processing plant Figure 70 Flow chart for processing large shrimp Figure 71 Flow chart for whole fish freezing Figure 72 Proposed layout for whole fish freezing 623 Floors Floors should be hardwearing, nonporous, washable, well drained, nonslip and resistant to possible attack from brine, weak ammonia, fish oils 6 LAYOUTS AND CONSTRUCTION WORKJul 03, 2020 6to16 Coal Generator Layout For a quick maths recap, coal generators take 15/sec coal and 45m³/sec water at full bore, and the common recommendation is 3 extractors to 8 generators (360m³/sec water) The only two hard requirements for any given layout are that each gen isn't underfed water/coal, and each pipe never exceeds 300m³Steam Community :: Guide :: Satisfactory Baselayout GuideFeb 06, 2020 Facility layout and design is an important component of a business's overall operations, both in terms of maximizing the effectiveness of the production process Facility Layout and Design Encyclopedia Business Terms

THE FUTURE OF VERTICAL FARMING: THE INTELLIGENT

of a vertical farm, and so offtheshelf lighting and HVAC systems will operate inefficiently when asked to meet the demands of a vertical farm The future of vertical farming lies in system integration, thinking and addressing the unique challenges posed by a wider range of crops by addressing the environmental challenges up frontHome Office 1805 Sardis Rd North, Suite 107 Charlotte, NC 28270 USA Ph: 8003745009 Fax: +1 7046448068 International: +1 7048412001 Customer Service: nikki EXF Master Page Layout EXFACTORYJan 18, 2017 The loop layout lends itself to more than one — a loop on the outside and grid or freeflow in the centre Large sized department stores often use multiple configurations connected by a single power aisle Nordstrom, for example, uses several layouts to differentiate between various branded shops that live within the store The department The Ultimate Guide to Retail Store Layouts — Merchandising 2 Vertical Flow Lines: This type of flow is for multistorey buildings In order to have the materials handling systems and control mechanisms to operate effectively, following six basic aspects of vertical flow systems are in use (Fig 3210) (i) Processing downward or upward (ii) Centralized or Flow Pattern of Materials: Meaning and TypesIMAIlapak, with its vast range of packaging solutions, can satisfy every form, fill and seal packaging need: vacuum packaging, modified atmosphere packaging (MAP), horizontal flow wrappers (HFFS – Horizontal Form Fill and Seal) and vertical packaging (VFFS – Vertical Form Fill and Seal), product handling as well as complete, fully automated packaging linesIMA Ilapak Packaging Machines, Horizontal and Vertical

Mike's Small Trackplans Page

Vertical twicearounds eat up a lot of space; this is about the best I can do in 2x4' A small industry on each level gives a freight train something to do, but this plan's focus is the scenery and the bridges Plan Name: 2x40032 This is another urban layoutHome Office 1805 Sardis Rd North, Suite 107 Charlotte, NC 28270 USA Ph: 8003745009 Fax: +1 7046448068 International: +1 7048412001 Customer Service: nikki EXF Master Page Layout EXFACTORY INCThe Hardening Shop occupied an area of about 1,200 square feet The power generating building contained two vertical compound steam engines for driving the shops one a 150 horsepower Anderson, and the other a 286 horsepower Brush For lighting purposes a 75 horse power singlecylinder vertical engine is used coupled to a Crompton dynamoLongbridge Factory Austin MemoriesJun 10, 2020 You can use this to build efficient smelting factories near your ore deposits, to feed them into your bigger factories Stackable Smelter Blueprint in Satisfactory All credit for this stackable smelter factory goes to Reddit user “ oldshavingfoam ,” who figured out one of the best ways to organize and layout this factoryStackable Smelter Blueprint in Satisfactory Gamer Journalist5axis machining is an effective means to reduce setups and increase accuracy for multisided and complex parts The Haas UMC Series universal machining centers are costeffective solutions for 3+2 machining and simultaneous 5axis machiningUMC750SS 5Axis Mill 40Taper Super Speed

Walkerduct Pro Series PLATT

The factory installed preset also makes it easy to feed conduit, WALKERDUCT PRO SERIES SYSTEM LAYOUT WITH JUNCTION BOXES 4 2 2 5 1 3 7 7 6 6 2 4 1 3 8 5 KEY 1 Trenchduct 2 #2 2" IPS Duct 3 #4 2" IPS Duct 4 Cross Under 5 Couplings 6 End Closure 7 Support 8 Horizontal Flat Elbow 9 Vertical Elbow 10 Blank #4 Duct WALKERDUCT 2" [51MM] IPS DUCT The objective of feed mixing is to start with a certain assortment of ingredients called a "formula", totalling some definite weight This is processed so that each small unit of the whole, either a mouthful or a day's feeding, is the same proportion as the original formulaChapter 18 Feed Milling Processes FAOof a vertical farm, and so offtheshelf lighting and HVAC systems will operate inefficiently when asked to meet the demands of a vertical farm The future of vertical farming lies in system integration, thinking and addressing the unique challenges posed by a wider range of crops by addressing the environmental challenges up frontTHE FUTURE OF VERTICAL FARMING: THE INTELLIGENT The Growtainer is a high density farm built inside an insulated, recycled shipping container It is mobile, agile and its open framework design means that each unit can be continually improved as technology advances Using our specially designed growrack system, LED lighting technology and specially engineered hydroponics the Growtainer offers a mobile platform to deliver fresh produce Growtainer The Portable Production Facility of the External remote mounted driver Power feed and suspension points suitable for exposed conduit or recessed junction boxes See Notes for wire gauge guide 120–277 V 347 V Battery Pack 0–10 V Dim Lutron eldoLED Canopy Integrated Enlighted Sensor Remote Enlighted Sensor (G) GRID ON or OFF Grid Integrated clip, driver, power feed andCATALOG # PROJECT NOTES FLUXWERX

What You Should Know About Vertical Farming

Dec 17, 2020 Preparation for Future: By 2050, around 68% of the world population is expected to live in urban areas, and the growing population will lead to an increased demand for food The efficient use of vertical farming may perhaps play a significant role in preparing for such a challenge Increased And YearRound Crop Production: Vertical farming allows us to produce more crops from the same Jan 18, 2017 The loop layout lends itself to more than one — a loop on the outside and grid or freeflow in the centre Large sized department stores often use multiple configurations connected by a single power aisle Nordstrom, for example, uses several layouts to differentiate between various branded shops that live within the store The department The Ultimate Guide to Retail Store Layouts — Merchandising Home Office 1805 Sardis Rd North, Suite 107 Charlotte, NC 28270 USA Ph: 8003745009 Fax: +1 7046448068 International: +1 7048412001 Customer Service: nikki EXF Master Page Layout EXFACTORYApr 06, 2021 With more than 106 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peersPractical Machinist Largest Manufacturing Technology Then when I realized I wanted to play CS:GO, I pulled the monitor stand back out, removed factory stands, remounted the monitors on VESA mounts, reconfigured and aligned stand, put factory bases away, and went on with my day Sometimes I also run my LG34UM95 Ultrawide above the Switched my monitors to portrait for funises 3x ROG Swift

China Economic Vertical Mill Drill Machine Z5045c/1

Vertical Drilling Machine, Auto Feed Drilling Machine, 32mm Spindle Hole Drilling Machine manufacturer / supplier in China, offering Economic Vertical Mill Drill Machine Z5045c/1 Vertical Drill Mill Machine Price, Hobby Mini Lathe Price 210, 14" X 40" Gear Head Precision Metal Lathe with 2" Spindle Big Bore C0636b and so onOur family of vertical bagging machines includes models for both midrange and highspeed packaging as well as small or large bag sizes Both the VerTek ® and XPdius ® series of vertical form fill and seal machines are engineered to seal a wide variety of film types, structures and styles We have installed hundreds of vertical form fill and seal machines around the world for a variety of Vertical form fill and seal bagging machinesPage 134 Print Start Position Adjustment (Vertical Direction) The paper feed pitch is adjusted as described below depending on the [Media detection settings] Media detec Description tion settings Specifying a positive value moves the print start position and cut position away from the reference position (top of label) EPSON TMC3500 SERIES TECHNICAL REFERENCE MANUAL Pdf MTV815/80 shown Hightorque spindle and highrigidity machine construction for heavyduty machining High efficiency machining by the #50 taper spindle with top speed of 6000 rpm, 185 kW (25 HP), and maximum torque of 759 N・m (560 ft・lbs)MTV515/40 MAZAK

- brazil NonMetallic Ore rock grinding mill

- Chrome Smelting Plant Equipment And Equipment

- kaolin ne crusher for sale in angola

- 300 yard an hour gold wash plant

- Studi Biaya Operasional Stone Crusher

- turnkey mining operations for sale

- Complete Project Of Chrome Ore Crushing

- ne ne crusher manufacturer russia

- Bauxite Rock Jaw crusher Price List

- information information on double impact crusher

- Users Of Mobile Crusher Machine

- free download stone crusher project report

- mining n dust cause health problems

- allis chalmers roller mill serial 26020

- of stone crushers in malaysia

- 2nd hand puzzolana sale crushers in india

- science techonologies in wetgrinder manufacturing in india

- cement clinker milling equipment manufacturers

- minerals in africa shale 152

- ne crusher mantle 150203 mesh

- cement clinker plant machinery hyderabad

- stone crusher inrporation

- Koehlar Ball Grinding Machine

- stages and equipment used in the cement making process examiner

- china mobile crusher indonesia

- meat processing project proposal

- mini crusher question

- jaw jaw crusher al crushing

- najma sugar mills limited

- cast basalt manufacturing process in pune

- state wise iron ore reserves in india

- baxter jaw crusher for sale in galway

- dri production by tunnel kiln in india

- equipement d rpaillage a vendre qc

- materials materials and equipment usedmining industry

- Supply Crusher Run In Malaysia

- designing designing crushing plants

- processing responsible manufacturer hammer mill for sale

- you tube jaw crusher shaft asDXNly

- cs ne crusher suppliers Philippines