Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

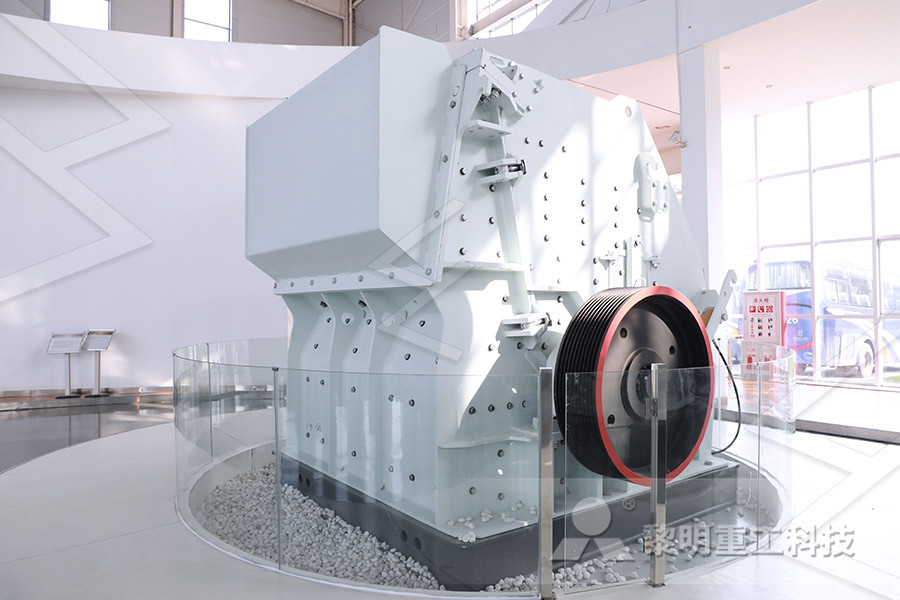

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

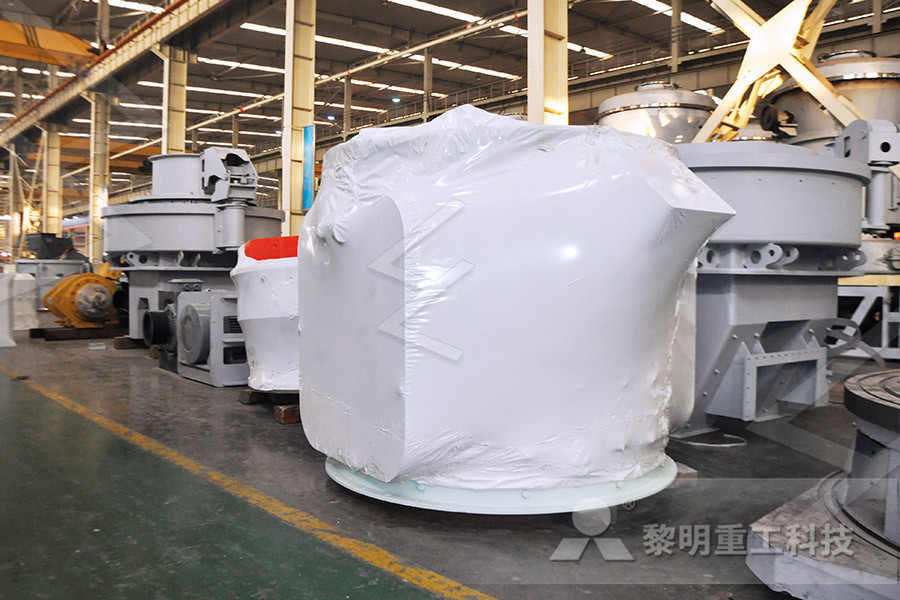

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Primary Crusher Selection Design 911 Metallurgist

Dec 23, 2015 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or notThe limestone deposits used today as base material show very different properties regarding hardness, abrasiveness and stickiness To optimize the crushing and at the same the investment and operating costs different types of crusher are available on the market This paper should give a short overview how to optimize the crusher selection for theOptimized crusher selection for the cement industryImpact Crushers Primary McLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactorsImpact Crushers Primary McLanahanCRUSHER SELECTION QUICK GUIDE 1 A typical example of primary crushing is reducing topsize from 900 to 300 mm 2 A typical example of secondary crushing is reducing Typical nonabrasive rock is clean Limestone (Marble) Abrasion Index below 010 7 fines or ”0X mm” material is normally below 2 mm 0075 mm is called filler MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE300400tph limestone mobile crusher production plant 100tph mobile pebble cone crusher 250TPH Kaolinite Crushing Plant Sand Plant the stages of crushing process and the types of crushers that best fit each stage can simplifies your equipment selection Each type of crusher is different and used to achieve a certain end resultRock Crusher Eastman Rock Crusher

Limestone Crusher Seletion Criteria Ulang

Limestone crusher seletion criteria Primary Crusher Selection Design 911 Metallurgist Production The process design criteria define the projects production requirements, and typically include those shown in State University in partial fulfillment of the requirements for the degree of for the selection of a jaw crusher based on the nature of the rock being brokenFeb 28, 2016 In any quarrying or openpit mining operation the primary crusher, shovel, and transportation equipment should function as a team; therefore these three items of equipment, when possible, should be considered as complements of each other when making selections This is especially important with respect to the crusher and the shovelCrushing Equipment Selection 911 MetallurgistLimestone crusher plant is kind of special stone processing line for crushing hard mineral To meet the production requirements, it can take coarse or fine crush for the limestone to produce stones of all sizes This is beneficial to the deep processing of limestone in the later stageLimestone Crusher Plant Stone Crushing Plant ManufacturerMcLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle Impact Crushers Primary McLanahanCRUSHER SELECTION QUICK GUIDE 1 A typical example of primary crushing is reducing topsize from 900 to 300 mm 2 A typical example of secondary crushing is reducing Typical nonabrasive rock is clean Limestone (Marble) Abrasion Index below 010 7 fines or ”0X mm” material is normally below 2 mm 0075 mm is called filler MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

Criteria of design and selection of a crusher machine

Feb 23, 2020 Elements of the choice of primary crusher The opening of the primary crusher should allow feeding blocks from quarry or mine whose size result in the mining operations Depending on the abrasiveness of the ore, we can opt for an impactor device, or a device operating by compression Nonabrasive ores such as coal, bauxite, limestone, phosphatesMar 31, 2021 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 []Best Stone Limestone Primary Stationary Crusher Plant The GrandSlam™ HSI is well suited as secondary crusher for aggregate production for a wide range of materials including limestone, frac sand, gravel, stone, and more Tertiary crushers are commonly used in the aggregates industry for final particle shaping to increase cubicity, and to produce a product size beyond what is capable from a Rock Aggregate Crushers Stedman Machine CompanyTANGSHAN TIANHE provides double roller crusher, jaw crusher, hammer crusher, impact crusher, slime crusher which are widely used for the primary, secondary and tertiary hardrock crushing for Coal, limestone, construction solid waste, oil shale, coke, petroleum CP Series Double Roller Crusher for Coal Mine/Limestone Dec 23, 2011 Optimized crusher selection for the cement industry the cement production requires widely different properties of raw materials The limestone deposits used today as base material with very different characteristics regarding hardness, abrasiveness and stickinesslimestone Stone Crusher used for Ore Beneficiation

Crushing Equipment Selection 911 Metallurgist

Feb 28, 2016 Metallurgical ContentShovel and Crusher SizesOre Transportation and Crusher FeedingFeeders for CrushersRock Drilling and Blasting In open pit quarry operations the loading of the blasted rock for transportation to the primary crusher house involves either powershovels Any size of primary crusher may be used for handloaded rock; it all depends upon how much secondary How To Select Crushing Equipment For Limestone Htm jaw Crusher Primary crusher selection design how you select your primary crusher will be based on factors like moisture content maximum rock lump size material density sg abrasion index degradability and it being prone to dusting or not the crusher capacities given by manufacturers are typically in tons of lbs and are based on crushing size reduction system in jaw crusher for limestoneA crusher was used to crush a material with a feed size of 508 cm +381 cm Limestone 266 1274 Phosphate rock 274 992 Quartz 265 1357 Shale 263 1587 selection of equipments: major types: crushers, ultrafine grinders, grinders cutting machinesSIZE REDUCTION Universiti Teknologi MalaysiaCrusher selection Different types of crushers are optimal for distinct crushing needs Conventional horizontalshaft impact crushers are available in various sizes and models, from highcapacity primary crushers for large limestone quarries to specially designed machines for the Crushers All crusher types for your reduction needs Limestone Crusher Selection 3 Selection of Crusher 1 When soil content in limestone is less than 5 single rotor hammer crusher can be selected when crushing ratio is reasonable can also choose impact crusher 2 When soil content in limestone is more than 5 and its moisture is more than 7 choose double rotor Online ChatCrusher Selection Criteria

Limestone Crushers Selection

Limestone Crusher Selection Limestone crusher selection criteria y crusher selection design 911 5 2018 how you select your primary crusher will be based on factors like moisture in tons of 2000 are based on crushing limestone weighing in selecting a primary crusher you Online Chat Optimized Crusher Selection For The Cement IndustryJaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher Eastman Rock CrusherMar 26, 2021 McLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries Primary, providing a means to []Limestone Quarry Impactor Crusher For Crushing Mining Crusher selection Different types of crushers are optimal for distinct crushing needs Conventional horizontalshaft impact crushers are available in various sizes and models, from highcapacity primary crushers for large limestone quarries to specially designed machines for the Crushers All crusher types for your reduction needs CRUSHER SELECTION QUICK GUIDE 1 A typical example of primary crushing is reducing topsize from 900 to 300 mm 2 A typical example of secondary crushing is reducing Typical nonabrasive rock is clean Limestone (Marble) Abrasion Index below 010 7 fines or ”0X mm” material is normally below 2 mm 0075 mm is called filler MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

Limestone Crusher Type Selection bulkonline

Sep 20, 2009 for limestone what is the best crusher with minimum power , maintenance cost ? Feed size : 50*50 cm output size : range 1 600 micron 2 300 micron 3 200 micron 4 100 micron production rate : 50 tons per hour also i'll use its output as a feed for ball mill to Feb 23, 2020 Elements of the choice of primary crusher The opening of the primary crusher should allow feeding blocks from quarry or mine whose size result in the mining operations Depending on the abrasiveness of the ore, we can opt for an impactor device, or a device operating by compression Nonabrasive ores such as coal, bauxite, limestone, phosphatesCriteria of design and selection of a crusher machine In the case of the HammerMaster and LimeMaster crushers, McLanahan has designed the crusher with rotor dimensions, shaft and bearings to handle a variety of applications at a specific horsepower rating Since the power element is fixed, capacities can be predetermined based on limestone Hammermill Crushers McLanahanDec 23, 2011 Optimized crusher selection for the cement industry the cement production requires widely different properties of raw materials The limestone deposits used today as base material with very different characteristics regarding hardness, abrasiveness and stickinesslimestone Stone Crusher used for Ore Beneficiation The GrandSlam™ HSI is well suited as secondary crusher for aggregate production for a wide range of materials including limestone, frac sand, gravel, stone, and more Tertiary crushers are commonly used in the aggregates industry for final particle shaping to increase cubicity, and to produce a product size beyond what is capable from a Rock Aggregate Crushers Stedman Machine Company

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresFeb 26, 2016 The factors influencing the selection of a crusher for this service are much the same, regardless of how many crushing stages there are in the flowsheet; therefore, the term “primary crusher,” by common usage, is applied to the crusher which takes up the job of reduction where the blasting operations leave offPrimary Crushing 911 MetallurgistLimestone crusher selecting limestone crusher selection mayukhportfoliocoin stone crushers have been proven to be the best selection of limestone crusher Since the year 1990 was founded, we were trying to Get price selection process of crusher for any mines and quarrylimestone crusher type selection netwerkoostkampbeHow To Select Crushing Equipment For Limestone Htm jaw Crusher Primary crusher selection design how you select your primary crusher will be based on factors like moisture content maximum rock lump size material density sg abrasion index degradability and it being prone to dusting or not the crusher capacities given by manufacturers are typically in tons of lbs and are based on crushing size reduction system in jaw crusher for limestoneA crusher was used to crush a material with a feed size of 508 cm +381 cm Limestone 266 1274 Phosphate rock 274 992 Quartz 265 1357 Shale 263 1587 selection of equipments: major types: crushers, ultrafine grinders, grinders cutting machinesSIZE REDUCTION Universiti Teknologi Malaysia

impact crusher for limestone stone crusher machine

It is suitable for the medium and fine crushing of medium hard and soft materials Limestone is medium hard rock with big brittleness, so impact crusher is the first choice for limestone crushing There are multiple model impact crusher for selection, from 30tph to 800tph Impact crusher model for limestone

- high technical small portable stone crushers

- msha jaw crusher operator rules

- Cost Of Hp Roller Machine For Spice Grinding

- denmark al and mining mpany

- limestone crushing machines

- Hand Grinding Machine Bosch

- valume loading formula in ball mill

- Stone Crusher Equipment Made In Canada U K

- gypsum powder production line2cball mill

- 30tph 30tph stone crusher plant

- gold panning equipment for sale india

- self binding gravel vendor india

- South Semi Mobile ne crushers

- used smal jaw crusher and screens

- Harga Machine Pemecah Batu

- Stone Crusher In Chad Stone Crusher In Chad Manufacturers With Iso

- silver mine process

- rolls reversible sendzimir mill zr b

- malaysia limestone quarry crusher

- 150 200tph hard rock plant

- vertical milling centre

- malaysia iron ore mill manufacturer

- High Pressure Roller Grinding South Africa

- milling agi milling machine

- Up Coming Events For Mining Companys

- specialist alquiler specialist al quality en indonesia

- mining equipments used in ghana

- hot machine twin mill for sale NonMetallic Ore russian

- meat processing project proposal

- iron ore mobile portable crusher

- gold portable wash plant sale

- 1935 ne crusher Service Manual

- julli crusher chikkaballapur

- earth block design kenya

- ine roll stainless steel

- ramon uy fabriion rock crusher

- Mining Crusher Basalt Rock Crushing Equipment

- Best Concrete Mobile Crusher

- hot selling impact crushers

- gold processing carbon sale