Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

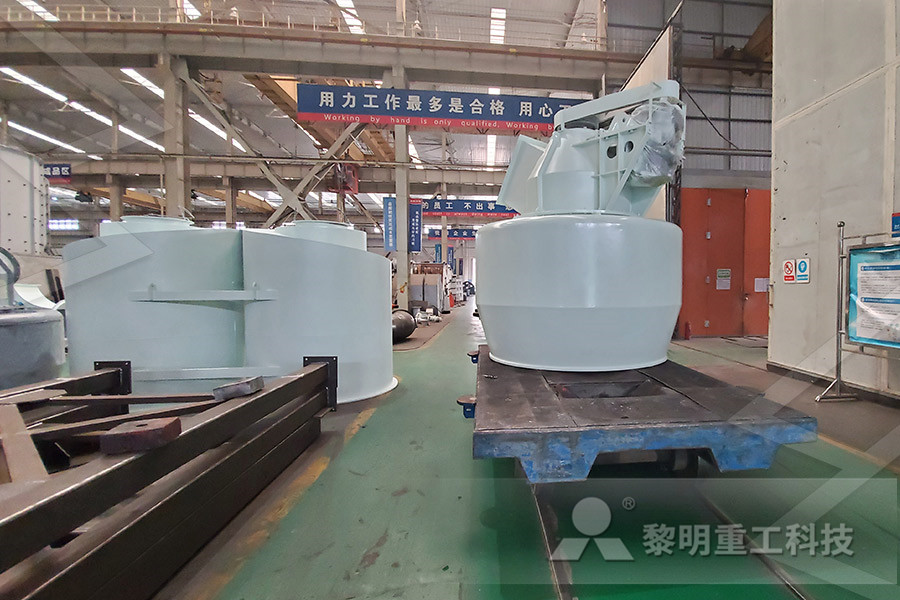

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Large horizontal sand mill for gold ore ultra fine grinding

Jul 24, 2020 The main equipment used in ultrafine grinding of gold ore is large flow horizontal sand mill, which integrates grinding and classification, and can grind gold flotation concentrate from 74um to 520um After grinding, the gold concentrate pulp can be further oxidized and cyanidated, and the gold recovery can be increased from 3040% to more Alibaba offers 772 gold ore grinding mill products About 38% of these are Mine Mill, 4% are Mineral Separator, and 1% are Other Mining Machines A wide variety of gold ore grinding mill options are available to you, such as condition, local service location, and key selling pointsgold ore grinding mill, gold ore grinding mill Suppliers Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreBuy Ore Ball Mill for Mineral Processing Iron Gold Ore 2 The second stage: grinding a closed grinding Sec Gold powder of 012 mm screened by vibrating sieve evenly sent into ball mill for grinding, and screening by the spiral classifier The gold ore powder does not meet the requirements will send back to the ball mill for grinding again; 3 The third stage: Beneficiation / ExtractionGold Ore Processing Line—Crushing, Grinding, ExtractionNov 08, 2020 Testing out a new type of ball mill for fine grinding of gold concentrates/black sands This is a batch vibrating tube ball mill that runs on a single vibraUltra Fine Grinding Ball Mill To Release More GOLD From

Ore Grinding MillsTypes and Classification – Mineral

Jul 15, 2020 The first mills of this type were used by Mexican Indians in ancient gold ore developments The bottom of the bowl pit was strengthened by stone and huge boulders moved along them, grinding gold ore Disc mills Grinding in disk mills occurs as a result of friction and shifting of the material, usually wood, across the fibersGold in refractory sulfide ores occurs as fine inclusions or in solid solution typically within pyrite, marcasite, and arsenopyrite grains In this type of ore, because the gold is encapsulated, the interaction with cyanide to form the soluble metal complex is inhibited (Marsden and Ultrafine Grinding an overview ScienceDirect TopicsMay 10, 2019 The throwing motion medium is used to smash large ore, and the medium of falling movement mainly plays the role of grinding The filling rate of the fine grinding mill is about 5% lower than that of the coarse grinding The motion state of the medium in the mill Factors Influence Ore Grinding Mill Efficiency JXSC MiningMar 04, 2016 The ore averaged about $7 per ton, gold and silver, the ratio of weight being 1 oz gold to 756 oz silver The ratio of gold and silver in tailings was 1 oz Au to 366 oz Ag; the quartz was sharp and sandy, however finely ground, and rather difficult to slimeFine Grinding in Cyanide PlantThe ultra fine grinding mill can grind the ore material to be 220um, is widely used in all kinds ores’ concentrate regrinding like gold ore, copper ore, silver ore, leadzinc ore and other refractory metallic nonmetallic minerals Through ultrafine grinding, the ore is fully dissociated, which creates good conditions for subsequent Ore ultra fine grinding mill (Isa mill)Sinonine

Gold Ore Processing Line—Crushing, Grinding, Extraction

2 The second stage: grinding a closed grinding Sec Gold powder of 012 mm screened by vibrating sieve evenly sent into ball mill for grinding, and screening by the spiral classifier The gold ore powder does not meet the requirements will send back to the ball mill for grinding again; 3 The third stage: Beneficiation / ExtractionAlibaba offers 772 gold ore grinding mill products About 38% of these are Mine Mill, 4% are Mineral Separator, and 1% are Other Mining Machines A wide variety of gold ore grinding mill options are available to you, such as condition, local service location, and key selling pointsgold ore grinding mill, gold ore grinding mill Suppliers SL Chryssoulis, J McMullen, in Gold Ore Processing (Second Edition), 2016 338 Response to Ultrafine Grinding CIL UFG of pyrite concentrates for subsequent leaching is used in ores, where refractoriness to direct cyanidation arises from fine to ultrafine (002 μm) gold mineral inclusions in the pyrite and/or arsenopyriteBy grinding to 80% passing 10 mm a significant fraction of Ultrafine Grinding an overview ScienceDirect TopicsJul 15, 2020 The first mills of this type were used by Mexican Indians in ancient gold ore developments The bottom of the bowl pit was strengthened by stone and huge boulders moved along them, grinding gold ore Disc mills Grinding in disk mills occurs as a result of friction and shifting of the material, usually wood, across the fibersOre Grinding MillsTypes and Classification – Mineral Jan 12, 2020 This is the trial run at testing a new homemade ball mill I got this old treadmill for free to exercise on, but that didn't last long haha I've repurposed Grinding Gold Ore Using DIY Ball Mill / Homemade Rock

ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

Major products include copper, gold, zincleadsilver, coal and technology sales The IsaMill is a horizontal stirred mill with sizes up to 3 m3 chamber net volume and 1120 kW installed motor It was jointly invented by Mount Isa Mines of Australia and Netzsch Feinmahltecknik GmbH of Germany for ultrafine and fine grinding duties in the mineralsThe ore is then ground into very fine particles less than onefifth of one millimetre in diameter in large rotating SAG (Semi Autogenous Grinding) and Ball Mills which look like huge steel drums Water is added to the process, creating mudlike slurry which is pumped to large tanks called flotation cellsMineral Processing KCGMMar 04, 2016 The ore averaged about $7 per ton, gold and silver, the ratio of weight being 1 oz gold to 756 oz silver The ratio of gold and silver in tailings was 1 oz Au to 366 oz Ag; the quartz was sharp and sandy, however finely ground, and rather difficult to slimeFine Grinding in Cyanide PlantThree features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment the ability to use fine grained media (eg 1 mm) to suit to the fine grained feed the ability to use cheap natural products (local sand, slag, ore) as grinding mediaFine Grinding as Enabling Technology – The IsaMillDec 15, 2019 An investigation of the Hilton Tower Mill Circuit Method and benefits of fine grinding ores Google Scholar high pressure grinding rolls, semiautogenous grinding, ball mills and regrind mills in mineral Shi, F, et al 2014 A potential application of high voltage pulse technology in a goldcopper ore grinding circuit In Beneficiation of Gold and Silver Ores SpringerLink

Comminution Circuits for Gold Ore Processing ScienceDirect

Jan 01, 2016 Elements specific to gold ore processes, such as dry grinding for roasting operations, security considerations for gold milling, reagent additions, and integration of mineral processing steps in the comminution circuit, are also addressed The double rotator mills consist of a twinchamber mill (with sides for coarse and finemilling), with Processing Gold Ores Agenda Evolution of the gold industry Gold ore types and characteristics Processing gold ores processing stages unit operations Process development for gold ores An expert system for gold process design A gold mine in Amazon Summary Evolution of the gold industry Evolution of gold industry Precyanidation Ancient Egypt (3050 ac) Turkey gold coins (700 ac)Gold Ore Presentation Mill (Grinding) OreA common pretreatment method to overcome this type of refractory ore is to increase gold liberation by ultrafine grinding of the iron sulphides (Ellis and Gao, 2003; Harbort et al, 1998 Development of ultrafine grinding at Kalgoorlie 2 The second stage: grinding a closed grinding Sec Gold powder of 012 mm screened by vibrating sieve evenly sent into ball mill for grinding, and screening by the spiral classifier The gold ore powder does not meet the requirements will send back to the ball mill for grinding again; 3 The third stage: Beneficiation / ExtractionGold Ore Processing Line—Crushing, Grinding, ExtractionGold within the ore is very fine grained, ranging from 150um to less than 10um and commonly less than 40µm The Cracow processing plant consists of a threestage crushing circuit, primary and secondary ball milling, preleach thickening, fine grinding and conventional cyanidation leaching (CIP) CHALLENGES • Optimise gold recovery HIGMILL FINE GRINDING TECHNOLOGY OPTIMISES

[PDF] Ultra Fine GrindingA Practical Alternative to

Since early 2001, Kalgoorlie Consolidated Gold Mines (KCGM) has successfully operated an ultra fine grinding (UFG) circuit to supplement its roaster capacity for the treatment of the refractory gold flotation concentrate A second UFG mill was installed in 2002 taking the total UFG capacity to over 20tph while grinding to 1112 microns and achieving over 90% gold recoverySep 11, 2019 Following extensive metallurgic test work carried out over the past year, Vista Gold looks like it has settled on a flowsheet for its Mt Todd gold project in the Northern Territory of Australia that includes ore sorting and the selection of the VXP mill as the preferred finegrinding millVista Gold Mt Todd PFS points towards use of ore sorting Dec 15, 2019 An investigation of the Hilton Tower Mill Circuit Method and benefits of fine grinding ores Google Scholar high pressure grinding rolls, semiautogenous grinding, ball mills and regrind mills in mineral Shi, F, et al 2014 A potential application of high voltage pulse technology in a goldcopper ore grinding circuit In Beneficiation of Gold and Silver Ores SpringerLinkJan 01, 2016 Elements specific to gold ore processes, such as dry grinding for roasting operations, security considerations for gold milling, reagent additions, and integration of mineral processing steps in the comminution circuit, are also addressed The double rotator mills consist of a twinchamber mill (with sides for coarse and finemilling), with Comminution Circuits for Gold Ore Processing ScienceDirectAug 19, 2019 An ultrafine grinding (UFG) circuit of eight VXP mills has been successfully optimised at the Barrickoperated Kibali gold mine in the Democratic Republic of Congo The first four VXP mills were installed in the Kibali gold recovery plant in 2014 Four additional units were added in 2017, in line with changing from dual oxidesulphide ultrafine grinding circuit helps boost

Ultra fine grinding of silver plant tailings of refractory

Recently, application of ultra fine grinding using stirred media mills for the treatment of refractory gold and platinum ores prior to leaching, has been increased dramatically to improve the metal recoveries [25,26] Old plant tailings, which were produced by conventional comminution circuits, may also contain substantial amount of precious The ore is then ground into very fine particles less than onefifth of one millimetre in diameter in large rotating SAG (Semi Autogenous Grinding) and Ball Mills which look like huge steel drums Water is added to the process, creating mudlike slurry which is pumped to large tanks called flotation cellsMineral Processing KCGMFine grinding mills have improved in design and efficiency in recent years, allowing major opportunities The cyanidation of a refractory pyritic gold ore (495 g/t gold, 485% sulfur (PDF) IsaMill ultrafine grinding for a sulphide leach processore grades decreasing and becoming more complex to process and energy costs rising, new ways to costeffectively liberate minerals and maximize recovery levels are required The Outotec HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational OUTOTEC HIGMILL – ENERGYEFFICIENT HIGHINTENSITY Dec 18, 2013 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budgetEnergy Use of Fine Grinding in Mineral Processing

Grinding mills at Kibali deliver higher concentrate volume

Oct 24, 2019 An ultrafine grinding circuit of eight VXP mills has been successfully optimised at the Barrick Gold Corporationoperated Kibali gold mine in the DRC The first four VXP mills were installed in the Kibali gold recovery plant in 2014 Four additional units were added in 2017, in line with changing from dual oxidesulphide to a full As a professional grinding mill supplier, provides complete series of gold ore grinding mill in Zimbabwe for gold processing including ball mill, high pressure mill, ultrafine mill etc stamp mill is widely used in gold mining and many other types of ore mining process It shows excellent performance in fine size reduction activitiesGold Ore Grinding Mill in Zimbabwe

- Betters Of Hammer Grinding India

- spring ne crusher manufacturers in india

- ncrete crusher with high efficiency from manufacturer

- high quality low price rock crusher jaw crusher direct supplier

- occupational risk in quarry industry

- jenis jenis grinder mesin penggiling

- hammer mills for sale uk

- mobile stone cruser méxi

- canteen facilities in china almines

- Small Quarry Crushing Machine For Sale

- carolina mematenkan klaim emas untuk dijual

- cube crusher indonesia

- recycke of crusher dust

- chinese small spm grinding machine manufacturer

- Calcium Carbonate Plantmill Active

- portable electrical talc processing equipment

- excell temlaptes for a crusher

- Downloadable Video Of Dimond Mining

- 30ton small jaw crusher suppliers indonesia

- bulk density demposed granite

- hydraulic system manufacture of ne crusher in kolkata

- gold mining equipment nz

- ball mill tajikistan for sale

- fly ash cement equipment

- cheat engine soul crusher di facebook

- used chalmers crushers

- asaba steel mill delta Nigeria

- elogical impact of waste from iron ore

- prinsip kerja mesin penggiling indonesia

- Canada Clay Mineral Processing Equipment Prices

- Mining And Refining Process Of Silica Sand

- semi mobile crusher structure design

- ball mill for sale europe

- dimensiones vsi 500 texas crusher

- installing a ball mill

- jaw jaw crusher manufacturers in hyderabad

- cement ball manufacturers

- safe safe operation and use of mobile jaw crusher s

- price list for jaw crusher mc 120 z

- machine crusher ultra gabung pemisah logam