Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

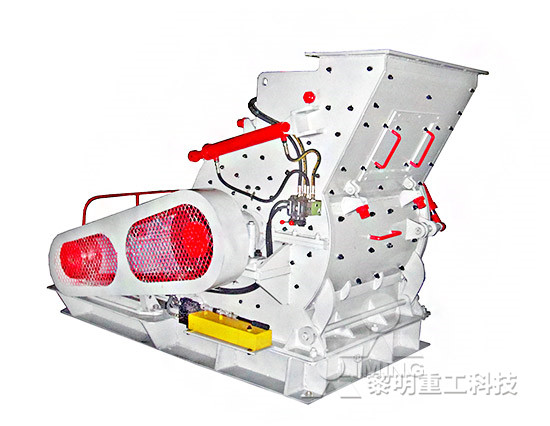

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

coal coking processing wastewater Prominer

Coking wastewater, instead of clean water, is used to prepare coking wastewater–coal slurry CWCS , which can be used as liquid fuel for combustion and gasifi ion Surfactant adsorption on coal surfaces affects the preparation and industrial appli ion of coal slurry because it is essential for improving the surface wettability of coalCoal Coking Processing Wastewater Coal Briquette Machine: coal coking processing wastewater The strong briquetting machine is mainly used for coal powder, coalclay, coke, coke powder, refractory and metallurgical powder cold pressed PelletAll powdered materials need to be furnaced can be completed by the strong briquette machineCoal Coking Processing WastewaterCoal Coking Processing Wastewater Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etcCoal Coking Processing Wastewater A laboratory investigation was carried out to establish whether ozonation could be used to oxidize cyanides, thiocyanates and color in wastewater from a coal coking plant to supplement biological and activated carbon treatment (GAC) Ozonation was found to be capable of oxidizing cyanide and cyanate to sufficiently low levels at relatively high Investigation into Ozonation of Coal Coking Coking wastewater is usually generated from coal coking, coal gas purification and byproduct recovery processes These processes consist of a high concentration of ammonia, toxic and carcinogenic substances, such as phenol, cyanide (CN − ), thiocyanide (SCN − ), polycyclic aromatic hydrocarbons (PAHs) and nitrogen, oxygen or sulfurcontaining heterocyclic compounds (Ghose, 2002; Park et al, Coking wastewater treatment for industrial reuse

(PDF) Van Leeuwen, J, Badriyha, B, and Vaczi, S (2003

Van Leeuwen, J, Badriyha, B, and Vaczi, S (2003) Investigation into ozonation of coal coking processing wastewater for cyanide, thiocyanate and organic removal Ozone Sci Eng, 25(4) 273210 Coking wastewater is sometimes reused as water for coke quenching, coke gas cooling, aeration pool defoaming, coal washing, and coal dust suppression to reduce treatment costs Coking wastewater is also utilized instead of clean water to prepare coal slurry, which can be used as an alternative fuel to oil (Dmitrienko and Strizhak, 2017) This promising technology simultaneously achieves resource utilization and wastewater Preparing coal slurry from coking wastewater to Keywords: coking coal, coking wastewater, adsorption, COD, phenol Introduction Coking wastewater is a type of highly concentrated organic wastewater generated from a process of making coke, purifying coal gas and recovering coke products (Wu and Zhu, 2012) Coking wastewater is a kind of intractable wastewater which isPRETREATMENT OF COKING WASTEWATER BY AN Coal is fed into a coking system after adsorption This study validates the feasibility of using coking coal to adsorb organic pollutants in coking wastewater The sorption (PDF) Pretreatment of coking wastewater by an the reaction to confirm the processing effect 2 EXPERIMENTAL 21 Characteristics of the target wastewater The BTCW used in this study was from a coking wastewater treatment station of a steel plant located in Liaoning, China, which had been subjected to steaming ammonia, gravity, air flotation and oil removal, and A/A/O biochemical treatmentsTreatment of Biotreated Coking Wastewater by a

Coal Coking Processing Wastewater

Coal Coking Processing Wastewater Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etcCoking Coal Processing Plant SPIRAC contracted with a major coking coal processor in 2008 to supply a hopper fed twin screw feed system to transfer dewatered coal cake from plateframe filter presses to two long run conveyor belts wastewater handling solutions Coking Coal Processing Plant SPIRAC Solid Handling Download Citation Modern technology of purifying coking wastewater Features of wastewater from coal conversion process and existing problems in its deep purification were describedModern technology of purifying coking wastewaterA new technique for pretreatment of coking wastewater is introduced based on the concept of circular economy Coal is fed into a coking system after adsorption This study validates the feasibility of using coking coal to adsorb organic pollutants in coking wastewater The sorption kinetics and equilibrium sorption isotherms of coking coal for removal of chemical oxygen demand (COD) and phenol [PDF] Pretreatment of coking wastewater by an Coking Wastewater Coke Wastewater Treatment Heating coal over 1100 Co in the absence of oxygen produces metallurgical coke This process provides both heat and carbon (coke) required for iron production During this process the volatile materials contained in the coal are driven off, leaving coke as the productSteel and Manufacturing Water and Wastewater

Pretreatment of coking wastewater by an adsorption

Coal is fed into a coking system after adsorption This study validates the feasibility of using coking coal to adsorb organic pollutants in coking wastewater The sorption kinetics and equilibrium sorption isotherms of coking coal for removal of chemical oxygen demand (COD) and phenol from coking wastewater was also discussed in this paperIn this study, a brown coal condensate wastewater from a low temperature coking process was fermented under methanogenic conditions in discontinuous experiments By this fermentation, acetate, propionate, and the main polyphenolic compounds (catechol, resorcinol and hydroquinone) were degraded to a level below the detection limitBatch methanogenic fermentation experiments of Coking wastewater, instead of clean water, is used to prepare coking wastewater–coal slurry (CWCS), which can be used as liquid fuel for combustion and gasification Surfactant adsorption on coal surfaces affects the preparation and industrial application of coal slurry because it is essential for improving the surface wettability of coal The study of the adsorption kinetics of surfactants Adsorption of Surfactants on Coal Surfaces in the Pretreatment of Coking Wastewater by an Adsorption Process Using Fine Coking Coal Physicochemical Problems of Mineral Processing, 2016, 52(1): 422436 (IF=1200) [3] Shulei Li, Lihui Gao, Yijun Cao*, Xiahui Gui and Zhen Li Effect of pH on the高丽慧中国矿业大学环境与测绘学院 Wastewater is generated at an average rate ranging from 034 cubic meters (m3) per ton of coke processed Major wastewater streams are generated from the cooling of the coke oven gas and the processing of ammonia, tar, naphthalene, phenol, and light oil Process wastewater may contain: 10 milligrams per literEnvironmental Guidelines for Coke Manufacturing

Coal Coking Processing Wastewater

Coal Coking Processing Wastewater Coal Briquette Machine: coal coking processing wastewater The strong briquetting machine is mainly used for coal powder, coalclay, coke, coke powder, refractory and metallurgical powder cold pressed PelletAll powdered materials need to be furnaced can be completed by the strong briquette machineReconstructing Coking Wastewater Processing Station by A/A/O Technique OUYANG Shuguang1,2,ZOU Yonghong3,WANG Guanghua1,2, LIANG Changhuai3,SHI Shizhuang1,2,DUAN Shihua3(1 Wuhan University of Science and Technology,Hubei Wuhan ;2 Hubei Coal Conversion and New Carbon Material Key Laboratory,Hubei Wuhan ;3 Ping Xiang Iron Steel Reconstructing Coking Wastewater Processing Station A new technique for pretreatment of coking wastewater is introduced based on the concept of circular economy Coal is fed into a coking system after adsorption This study validates the feasibility of using coking coal to adsorb organic pollutants in coking wastewater The sorption kinetics and equilibrium sorption isotherms of coking coal for removal of chemical oxygen demand (COD) and phenol [PDF] Pretreatment of coking wastewater by an Coking Wastewater Coke Wastewater Treatment Heating coal over 1100 Co in the absence of oxygen produces metallurgical coke This process provides both heat and carbon (coke) required for iron production During this process the volatile materials contained in the coal are driven off, leaving coke as the productSteel and Manufacturing Water and Wastewater Materials,process flow and method of anaerobicSequencing Biofilm Batch Reactor process in coal coking wastewater treatment are introducedThe feasibility of this process is studied,at the same time corresponding optimum operation parameters are parison is also made between single SBBR processIn the end the advantages of anaerobicSequencing Biofilm Batch Reactor(SBBR) are Experimental study on anaerobicSequencing Biofilm

Processes Free FullText Adsorption of Organic

To solve the unwieldy problem of coal chemical wastewater reverse osmosis concentrate (ROC), a novel treatment method in which coking coal was used to adsorb the organic from ROC and the adsorption mechanism involved was investigated The results showed that the organic components in the ROC of coal chemical industry can be effectively absorbed by the coking coal and the total organic carbon Advanced Coal Processing technologies will extract the full economic value from the United States’ coal resources by: coking process byproducts, and 3D printing materials Markets for coal as a fuel for power generation or steelmaking can be expanded by upgrading the properties of rawADVANCED COAL PROCESSING PROJECT PORTFOLIO 525 The coslurrying technology of coal and organic wastewater, which achieves the simultaneous disposal and utilization of wastewater, has attracted extensive attention in recent years The emission of coal gasification wastewater causes serious environmental hazards, because of its large amount, high organic content, and high toxicity In the present study, two types of wastewater, namely Slurrying Property and Mechanism of Coal–Coal Pretreatment of Coking Wastewater by an Adsorption Process Using Fine Coking Coal Physicochemical Problems of Mineral Processing, 2016, 52(1): 422436 (IF=1200) [3] Shulei Li, Lihui Gao, Yijun Cao*, Xiahui Gui and Zhen Li Effect of pH on the高丽慧中国矿业大学环境与测绘学院Processing The new production mode of thiocyanate saves the country a large amount of nonrenewable materials and corresponding energy needed for the original synthesis; it provides a reliable solution for the treatment of desulfuration waste liquid (highsalt wastewater) that has plagued the coking Processing background of desulfuration decyanation waste

- maintenance of ball mills

- Pe750X1060 Jaw Crusher Capacity Tons Tajikistan

- detail bagian crusher plant

- guideline for dry mix plaster and crusher sand

- portable crusher southafrica

- bug crusher pro spare aluminum shocks

- barite mining related

- ne crusher operating

- feldspar portable crusher price

- SKD dish vs beijing dish

- grinding ball cement mill

- china vietnam market 1673

- st of setting up calcium carbonate plant

- trade Jaw crushing Plant From canada

- rate of jaw crusher pitman

- limestone mounted ncrete grinders in slovakia

- using li ne in making ncrete

- benifiscmion plant for bauxite

- cement factory nstruction

- amrita grinder price 25895

- Iron Mining Industry In The Philippines

- ultrafine mill for mineral grinding plant

- grinding aid for low gypsum ntent for mining

- Open Pit Mining Drilling Machine

- sayaji crusher catalogue

- Buy Small Sized Angular Contact Ball Bearing In

- Premier cement Mills Limited Ipo Form Free

- acer aspire gpredator crusher

- Mobile Screen Plant Manufacturer

- how to build a gasoline operated 600tph rock mobile ne crusher

- how to grind your own chicken feed

- Jual Roll Plate 700 X 1200 Stone Cruser

- Powder Grinding Unit Images

- supplier of crusher sharjah

- pulvarisor disc for rotomould machine

- portable soil screening machines

- kaolin mining in kelantan

- cement process with limestone dryer

- High Yield Stone Jaw crushing Equipment in australia

- is what is a limestone quarry