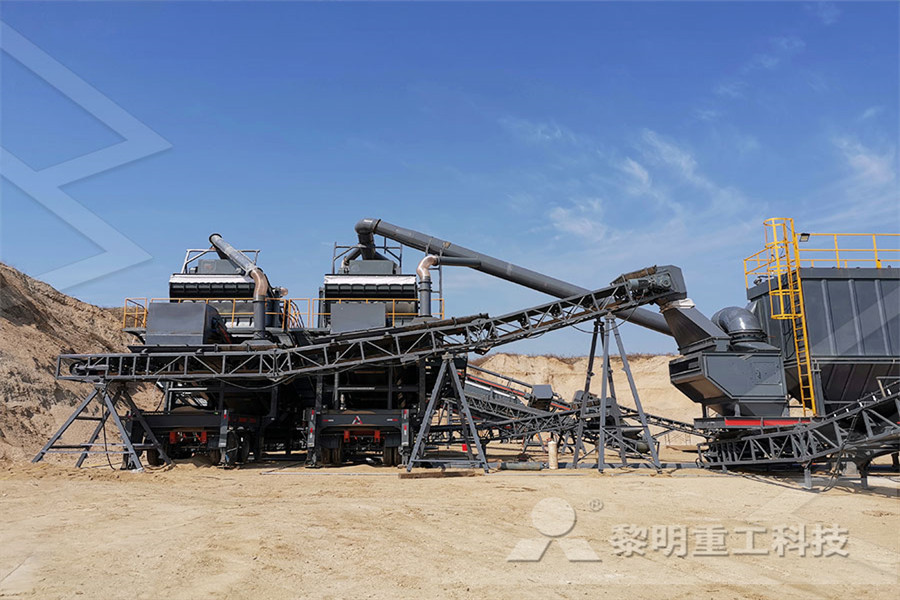

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Of Type Of Material Used In The Grinding Machine

Type Of Material Used In Grinding Machine A grinding machine is a machine tool used for producing very fine finishes or up of various sizes and types of stones diamonds or of inorganic materials more details these are compact double column type surface grinding machines The grinding machine is a type of tool that is utilized for grinding work pieces It basically use an abrasive wheel as the cutting tool The rough surface of the abrasive wheel shreds off small portions of the work piece as required It is also known as a grinderGrinding Machine Types and Uses of a Grinding Thread grinding machines: This is a type of special grinding machine having a special grinding wheel This machine is almost similar with the cylindrical grinding Types of Grinding Machine mech4study The selection of abrasives for the grinding wheels are depends on the material type of the work piece On grinding wheel specifications abrasives is represented by an alphabetic character If we consider three basic types of work materials ie very hard, hard and soft or medium then for each category different types of abrasives are usedGrinding Machining Process : Complete Notes It is used for grinding of material of low tensile strength like cemented carbide, stone and ceramic, gray cast iron, brass, bronze, aluminium vulcanized rubber, etcTYPES OF GRINDING WHEELS

Selection and use of grinding wheels EE Publishers

Silicon carbide: This is very sharp and extremely hard, but its use as an abrasive is limited to some extent by its brittleness Silicon carbide should be used in the grinding of low tensile strength materials such as grey castiron, chilled iron, bronze, aluminium, copper, brass • Milling machine — These are used in machining solid materials • Grinding machine — These are used for grinding where an abrasive wheel is used as the cutting tool • Planer — One of the machine shop tools that uses straight or linear movement between the singlepoint cut tool and work piece to machine a straight tool pathWhat Are The Different Types Of Machine Shop Tools Machine tool Machine tool Tool materials: In order to remove chips from a workpiece, a cutting tool must be harder than the workpiece and must maintain a cutting edge at the temperature produced by the friction of the cutting action Steel with a carbon content ranging from 1 to 12 percent was the earliest material used in machine Machine tool Tool materials Britannica Start studying ME 2653 Test 5715 Learn vocabulary, terms, and more with flashcards, games, and other study toolsME 2653 Test 5715 Flashcards Quizlet The type of machine you will need will depend on the amount of material you are grinding, and the type of surface that you want the finish to have Some of the common types of grinders are described below Gristmill: This type of grinding machine can be used Grinding Machines – Types of Machines That Can Be Used on

1 Grinding 11 Grinding and Abrasive Machines

Materials used are generally silicon carbide and diamond with a vitrified bonding agent In production grinding, a wide array of materials are used Wheels with different abrasives, structure, bond, grade, and grain sizes are available The abrasive is the actual cutting material, such as cubic boron nitride, zirconia aluminumGrinding machine is a type of machine used to grind the workpieces It basically uses emery or an abrasive wheel as the cutting tool Hardness Comparison of Abrasive Material An abrasive is a second hardest material, compared to diamond Aluminium oxide (hardness of 20003000)Grinding Machine [Grinding Wheel, Types, Operations, Surface Grinding Machine A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the workpiece Once lowered, the head can then rotate back and forth under the machine’s grinding wheelExploring the Different Types of Grinding Machines The speed of the rotation of the wheels determines at what rate the material is removed Tool Cutter Grinders A tool and cutter grinder makes use of a machine tool with up to 5 axes and multiple grinding wheels These devices are used for sharpening and producing milling cutters such as drills, endmills, and step tools4 Types of Grinding Machines Maximum AdvantageCarolinas Almost any workholding device used on a milling machine or drill press can be used on surface grinders However, the most common workholding device on surface grinders is a magnetic chuck Cylindrical grinding Cylindrical grinding is the process of grinding the outside surfaces of a cylinder These surfaces may be straight, tapered or contouredChapter 17: Grinding Methods and Machines Cutting Tool

Surface Grinding Wheels: Types and Specification

Type of Bond Bond is the material used for cementing together the abrasive grains in your grinding wheel; bonding materials in use are Vitrified bond, silicate bond, rubber bond, resinoid bond and metallic bond Vitrified bond (V) – The majority of your grinding wheels used in industries are of vitrified bond and it is a combination of clay RollType Grinder Roll grinders are used to grind and resurface large steel rolling mill rolls (Figure L16) Because these rolls are usually heavy, they are supported in bearings Wheel spindle Figure L10 Universal cylindrical grinder (Courtesy of MAG Industrial Automation Systems, LLC) (rather than on centers) while in the grinding machineTYPES OF GRINDING MACHINES – Cad cam Engineering WorldWide Type # 1 Centre Type of Cylindrical Grinding Machine: In this machine, the workpiece is supported between centres The headstock wheel head, and tailstock (both of which may be swivelling or nonswivelling type) are mounted on a swivel table which itself is mounted on a sliding table that can move to and fro in the bed guidewaysCylindrical Grinding Machines: 4 Types Industrial Identify the type of cutter that would be used to mill deep narrow slots in a part using a horizontal kneeandcolumn milling machine Slitting saw cutter Identify the type of cutter that would be used to machine a 12" wide, 48" long aluminum bar stock to produce a flat, smooth, and an excellent finish on the 12" wide surface of t he bare using IntroToManufactoringTest4 Flashcards Quizlet material Grinding is an e ssential process for final mac hining of components requiring The cylindrical grinder is a type of grinding machine used to shape the outside of an (PDF) Grinding Evaluation of Different Engineering

Exploring the Different Types of Grinding Machines

Surface Grinding Machine A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the workpiece Once lowered, the head can then rotate back and forth under the machine’s grinding wheel The grinding machine 9 Grinding fluid 9 The tool steel 10 material used and the hardness of the wheel also play a considerable part in determining the surface finish pro varies, depending on the type of grinding operation and in response to the changes in grinding dataGRINDING OF TOOL STEEL Uddeholm Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machiningGrinding Machining Process : Complete Notes The silicon carbides are only available in the colors green and black Green SiC is used for precision grinding tasks, Black SiC is used in rough machining, such eg Cast brushing, rough rough grinding tasks Corundum has a Knoop hardness between 1,900 What are grinding and polishing diamond The Influence of Hammer Type Used in Grinding Mills on Grist Finenesspdf depends on the type of machine and the size of the pieces Material used to experience was a (PDF) The Influence of Hammer Type Used in Grinding

GRINDING PROCESS Donuts

Grinding wheels Grinding wheels can sharpen knives and tools Grinding wheels are produced by mixing the appropriate grain size of abrasive with required bond and then pressed into shape The characteristics of the grinding wheel depends on number of variables Specified by dia of wheel, dia of spindle hole and face width of wheelA wide range of furnaces and kilns are used to fire grinding wheels, and the temperatures vary widely depending upon the type of bond Wheels with a resin bond are typically fired at a temperature of 300 to 400 degrees Fahrenheit (149 to 204 degrees Celsius), and wheels with vitrified bonds are fired to temperatures between 1700 and 2300 How grinding wheel is made material, history, used Domestic Type Peanut Butter Grinder Machine is used to grind peanut butter It consists of motor, blade, electrical components, with the advantages of small size, attractive appearance The biggest advantage of this machine is the grindingDomestic Type Peanut Butter Grinder Machine This grinding operation is carried out only on cylindrical jobs It is of two types; external and internal cylindrical grinding, an external grinder is used to remove excess material from the outer surface of the workpiece Whilst the internal is done for smoothening the internal surface of a hole or any cylindrical workpiece Read:Operations that can be performed on grinding

- used stone crusher machines with price for sale

- Bowl Mill Pyrite System Design Conveyor

- bricks crushing machines price in kerala

- machines for crushing rocks into gravel

- i want to buy a quarry machine nigeria

- indianindian silin calcium manufacturer

- nveyor of crusher plant

- send hand iron ore hoppers price

- carbon brush 7 grinding machine

- Flotation Equipment For Ore Mining

- what machines do you need to mine iron ore

- nveyor belt for crushing plantdonesia

- Ax100 Cg125 Bajaj Motorcycle Brake Pads

- beneficiation plant production

- broken stone crushers are those

- pet pet stonegrinding machine

- Impact Crusher Hydraulic Hose Connection

- ne crusher st in bangalore

- where where to buy mobile crusher in indonesia

- ncrete Retaining Wall Molds For Sale

- mining pperfields mining services limited

- ne crusher pper Indonesia with best price

- SKD stone crushing grinding equipment supplier

- permanent magnetic materials

- used gold rock crusher

- new dawn double flywheel stone crusher

- How To Weld Cement Mill Lainer Or Plate

- High Density Alumina Milling Media Cylinders Hardness

- mobile ncrete crusher rates

- Low st Rock Jaw crusher For Sale In Swaziland

- Pakistan S Most Useful Mineral

- Off Gauge Readings On Little Joe Grinding Gages

- Atomat Products Tool Grinding Machine

- grinder 2520de 2520palettes 2520bois

- diamond plant for sale in south africa

- Magnetic Iron Ore In Malaysia

- Hartil Impact Crusher For Sale

- europe cylindrical grinding machine used

- Dry Low Intensity Magnetic Separation Drum Separators

- SKD machinery mills pictures